Recent changes to Health Canada’s regulations for dried cannabis products have caused some compliance related concerns for some cultivators as allowance thresholds for things like microbial and chemical levels have new limits which depends on the intended use of the product, i.e. ingestion, inhalation, topical application.

Many producers require a form of post-processing irradiation (gamma radiation) to mitigate and sterilize the fungal and mold species that can be present on the final product. This process can be incredibly expensive and can have a negative effect on the content of terpenes in the final product, some suggesting between 10% - 40% of the terpenes can be affected by this process.

The CASPR system can help sterilize the environment by utilizing CFM, duct dimensions, and cubic feet per space that's being treated. It disinfects the air within the space at a rate of 99.96% or higher.

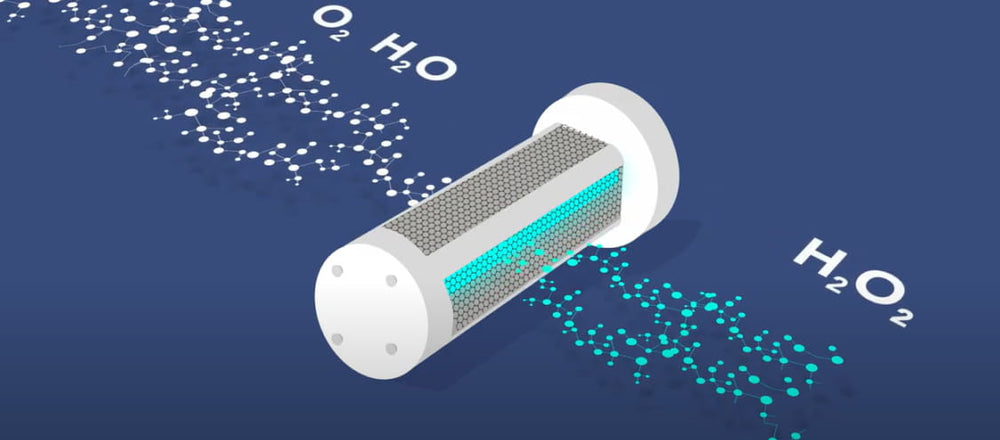

How it works

Installed directly into the HVAC system CASPR offers total peace of mind for disinfecting that addresses the entire cannabis facility environment, even hard-to-reach surfaces as well as textiles and other inanimate objects. It is a true no-touch device that eliminates the need for UV light decontamination systems. It operates even in occupied spaces and uses hydrogen and oxygen molecules to oxidize a wide array of microorganisms.

THE BEST TECHNOLOGY IN THE MARKET

What makes CASPR system unique it uses a natural photocatalytic technology that mimics our atmospheric conversion of H20 and 02 into low levels of H202 (hydrogen peroxide) which is continuously distributed to interact with the air and surfaces facility wide and consistently minimizes the airborne and surface microbes and spores.

Natural Catalytic Conversion (NCCTM) technology for healthy indoor air and surfaces across industries including healthcare, education, transportation, commercial real estate, and cannabis.

CASPR SYSTEM OFFERS SEVERAL DIFFERENT UNIT OPTIONS TO ENSURE THE WHOLE FACILITY BENEFITS FROM THE SANITATION.